Our press room features 15 to 30 ton high speed Bruderers. We are not just a light gauge specialist we also produce thicker, larger parts in a 5 ton press and a 45 ton Bliss press. Future planning includes a 60 ton press as we enter new markets and diversify. This sophisticated production equipment assures that parts are produced quickly and accurately while maintaining tight tolerances supplied in any configuration (individual pcs, strip form or reeled).

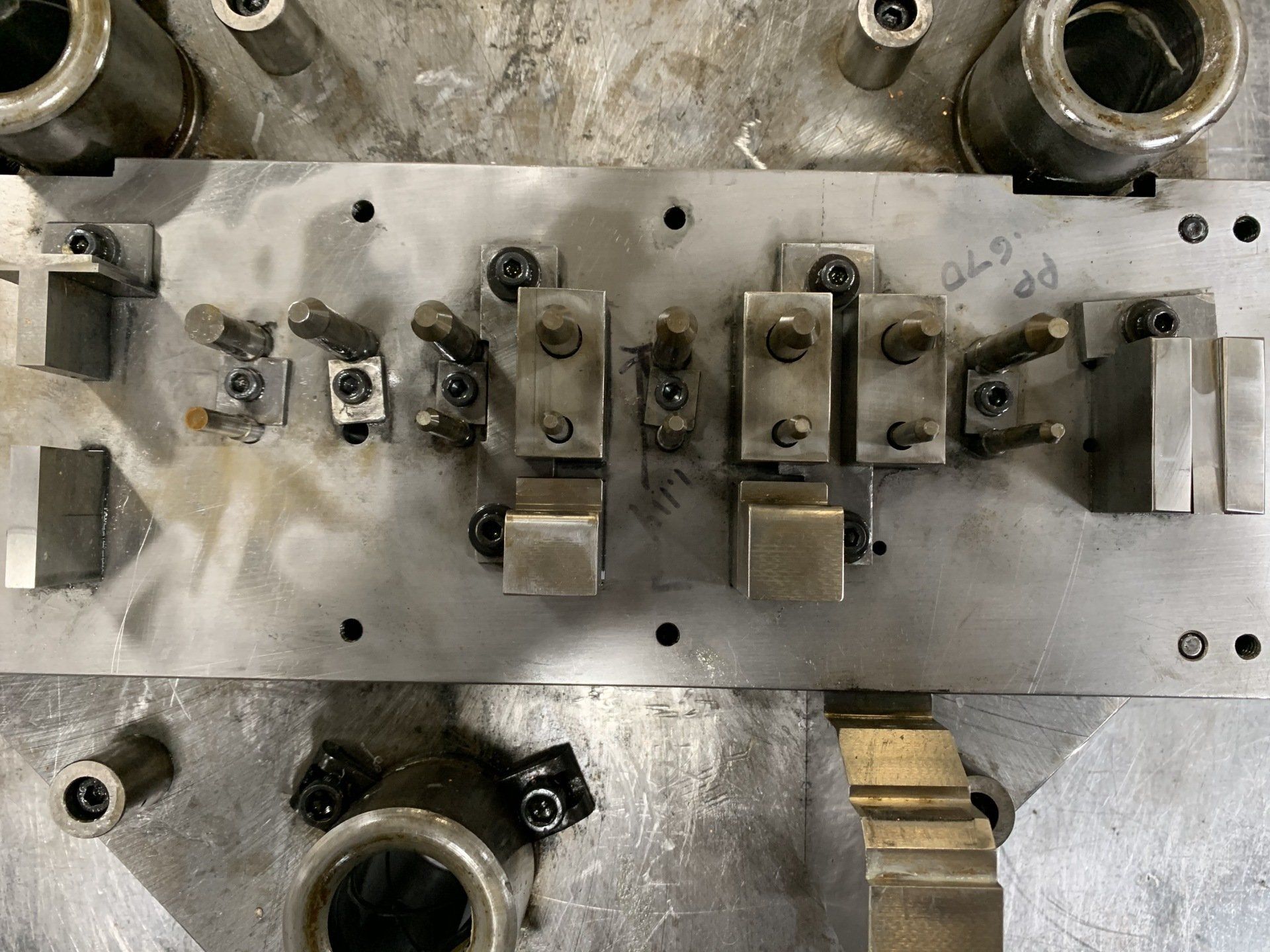

GSC produces many different parts for Automotive Electronics, Medical, Electrical and Hardware industries from leadframes to complex connectors. Our dies can include tapping, forming, coining and blanking. Materials used include Stainless Steels, Low Carbon and Spring Steels, Beryllium Copper, Copper, Brass, Phosbronze, Nickel, Alloy 42, Aluminum, Silver and Pre-Plated Materials ranging from .002 to .197 thick and tempers from Annealed to Full Hard.

Quality Control

and Certifications

We recognize that customer satisfaction is only achieved through an attention to detail and a respect for deadlines. General Stamping's quality control department meets or exceeds industry and military standards including a modern vision system. Our objective is to satisfy our customers with parts that consistently meet their requirements. Precision calibration equipment ensures that tolerances are met and quality is maintained at all times. This minimizes waste, reduces production time and eliminates post production problems. At GSC our most important measurement of quality assurance is the satisfaction of our customers. General Stamping is ISO 9001:2015 certified, ISO 14001:2015 certified and we are working towards IATF 16949 well known within the automotive industry.